How to choose the bubble film bag making machine that suits you

Basic Principle of Bubble Film Bag Making Machine

Bubble film bag making machine is a kind of equipment that makes bubble film into bag-shaped packaging materials. Its basic principle is to process bubble film into bag-shaped packaging materials through heating, top sealing, side sealing and other processes. Bubble film bag making machine is widely used in electronics, toys, gifts, lighting, watches, leather goods, food, medicine, cosmetics and other industries.

Classification of Bubble Film Bag Making Machines

According to their functions, bubble film bag making machines can be divided into bubble film bag making and sealing machines and bubble film bag making and forming machines. The bubble film bag making and sealing machines are used to seal bubble film and are generally used to make bags, while the bubble film bag making and forming machines are used to form bubble film into packaging materials of various shapes.

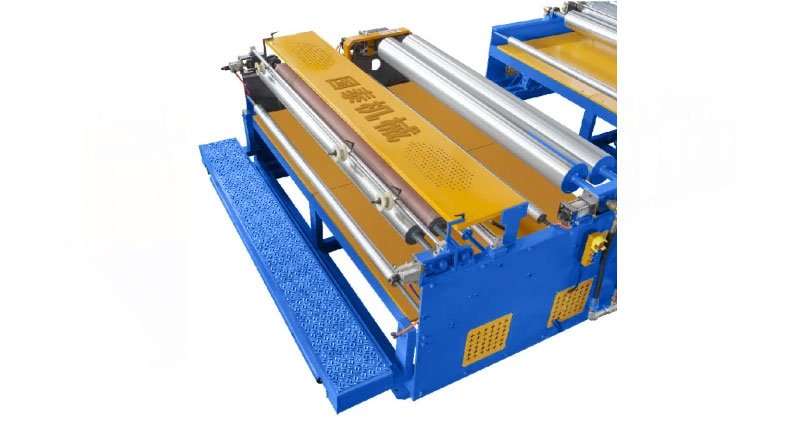

What are the parts of the bubble film machine?

Common parts of bubble film machines include gears, motors, sensors, heat sealing knives, pressure rollers, etc.

Gears

Gears are an important part of bubble film machines. They can realize rotational motion and transmit power. In bubble film machines, helical gears with spiral teeth are usually used. They can effectively reduce the noise when the teeth are meshed and improve the working efficiency and stability of the machine.

2. Motors

Bubble film machines require motors to provide power to work. Motors are usually divided into DC motors and AC motors. Since bubble film machines need to work stably for a long time, the stability and durability of the motor are very important.

3. Sensors

During the production process of bubble film machines, sensors can help monitor and control many key parameters, such as temperature, pressure, speed, etc. Through the data collected by the sensors, the machine can be adjusted according to the actual situation to improve production efficiency and quality.

4. Heat sealing knife

The heat sealing knife is one of the key parts of the bubble film machine. It can bond plastic materials to form the longitudinal sealing line of the bubble film. Heat sealing knives are usually made of nylon or stainless steel, with the characteristics of high temperature resistance, wear resistance, and corrosion resistance.

5. Pressure roller

The pressure roller can make the plastic sheet evenly fit to another sheet, so that the bubble film has a good appearance, and at the same time ensure the strength and sealing of the bubble film.

6. Other parts

In addition to the above parts, the bubble film machine also includes some other parts, such as heating system, cooling system, gas injection system, etc. All these parts work together in an orderly manner to finally realize the complete bubble film production process.

Air bubble wrap making machine have many advantages, including the following:

Lightweight and durable: Bubble film machines are usually made of high-strength aluminum alloy materials, with beautiful appearance, compact structure, easy to move and install, and can be used for a long time without being easily damaged.

High production efficiency: The production efficiency of bubble film machines is extremely high, and hundreds of meters of bubble film can be produced per minute, which greatly improves the production capacity of the packaging production line.

Excellent packaging effect: Bubble film materials have good cushioning properties, which can protect packaged items from damage by external forces such as impact and extrusion, thereby achieving good packaging effects. In addition, bubble film materials can also be used as functional materials such as heat insulation, moisture resistance, and dust resistance.

Low cost: Compared with other packaging materials, such as foam, cardboard, etc., bubble film materials are relatively light and have low production costs. And because of the easy packaging characteristics, the burden and freight of the transportation process are reduced.

How to choose a bubble film bag making machine that suits you?

1. Choose a model according to product requirements

When choosing a bubble film bag making machine, you need to choose a suitable machine according to your product requirements. Generally speaking, different models are suitable for different product types and specifications.

2. Choose a reliable brand

When choosing a Air bubble wrap making machine, you need to choose a brand with reliable quality and good after-sales service. The products of these brands have stable performance, high production efficiency, and perfect after-sales service, which can help customers solve various usage problems.

3. Choose a cost-effective model

When choosing a Bubble wrap manufacturing machine, you need to choose a cost-effective model according to your budget. Generally speaking, higher-priced models have higher production efficiency and stable performance, but not all users need these high-level functions.

4. Pay attention to safety performance

When using a bubble film bag making machine, you need to pay attention to its safety performance. First, you need to abide by the safety operating procedures and use the machine correctly; second, you need to pay attention to whether the machine's protective measures and safety devices are perfect to reduce the safety risks of operators in operation.

For You!