Our machines can recycle materials 100% and operate efficiently. Ordinary machines face increased mechanical wear due to impurities and variability in material quality. But the durability of our machine screws and barrel directly solves these problems, ensuring reliable operation and consistent product quality

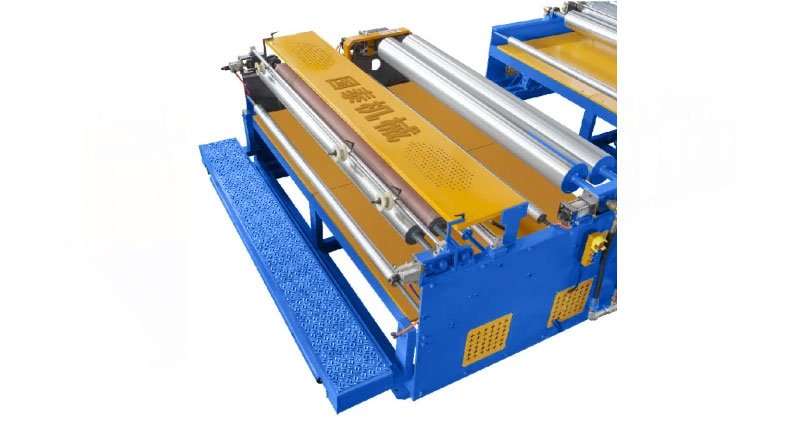

Mechanical overview

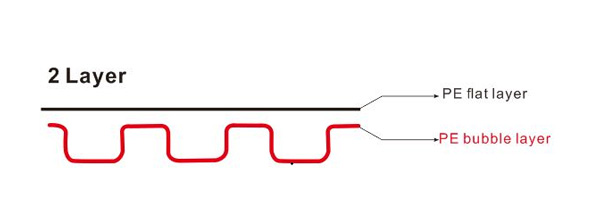

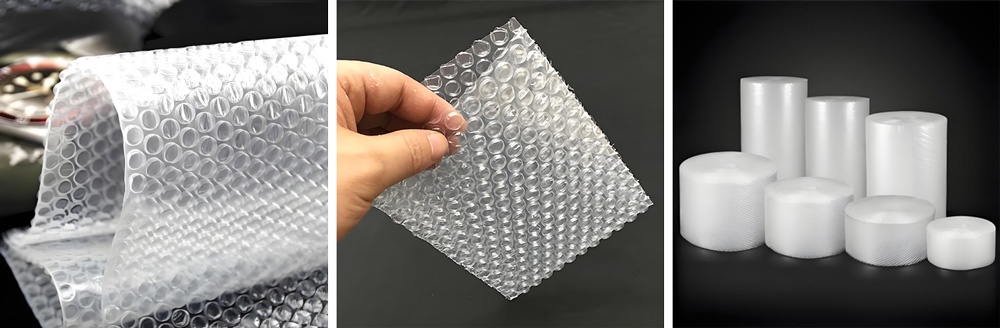

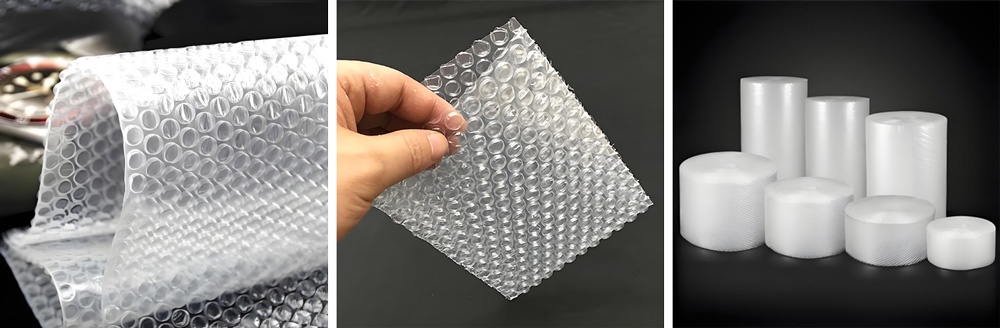

This machine uses LDPE,LLDPE granule material to produce air bubble film,which widely used as post parcel packing,precise instruments packing furniture packing etc.

This machine is composed of extruder,air bubble forming device,perforation device,winding device,cabinet control system.

Process flow

Bubble Film Machine Series Advantages

The main control system of the whole machine

The main control system of the whole machine is mainly composed of PLC control system, color touch human-machine interface, drive motor, AC digital loss inverter and electrical control cabinet. It is mainly used as the operation control part of the whole machine. The advanced control system can Make the whole machine run smoothly and efficiently.

Complete screw extruder unit

The main engine screw extrusion unit is mainly composed of AC digital frequency conversion motor, hard tooth surface reduction box, barrel, extrusion screw, connector, and screen changer. The main function is to suck the resin particles into the automatic suction machine. Enter the hopper and send it to the screw material port. The resin particles entering the screw are heated to a molten state and extruded forward to the screen changer. The filtered material is smoothly fed to the screen through the connector between the die and the screw. In the die head.

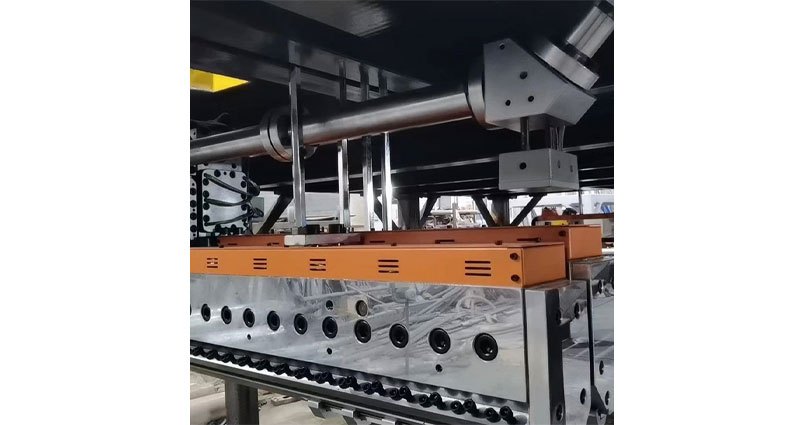

Extrusion die head

The extrusion flat die head is mainly made of multi-layer imported die steel after special quenching and tempering. It has a built-in hanger-type runner. The surface of the built-in runner is plated with imported hard chromium material, which has high hardness, corrosion resistance and reduced Adhesion and wear of resin to the runner of the flat die.

Main air bubble compound molding machine and transmission system

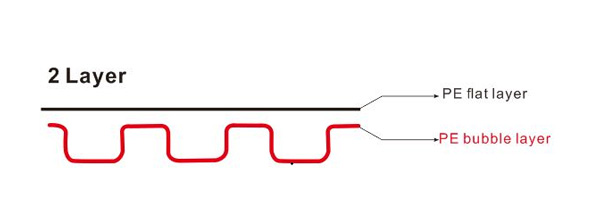

The main air bubble compound molding machine is mainly composed of air bubble rollers, pressure rollers, etc., each roller is equipped with a cooling circulating water system connected with a rotary joint. The transmission system equipped with a gear reducer connects each roller through a chain and a sprocket. The bubble roller is equipped with a vacuum negative pressure suction system. The main function of the main air bubble compound molding machine is to negatively negative the extruded two-layer sheet. Squeeze into film bubbles.

Online traction slitting unit

The online traction and slitting unit are mainly composed of flat rollers, pressure rollers, etc., each roller is equipped with a cooling circulating water system connected with a rotary joint, and the online slitting function is mainly composed of a knife holder, a blade, a waste guide rail, etc., The transmission system equipped with a gear reducer connects each roller through a chain and a sprocket. The main function of the main air bubble composite forming machine is to cut the air bubbles or composite air bubbles into materials of different widths online and send them to the winding device.

Half-automatic rewinding platform

The automatic cantilever winder is mainly composed of online storage flying knife scuttling system and dual electric winding system, which can automatically scuttling and winding according to the set length of the finished product.

Sample display

FAQ

Q: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q: How long is your delivery time?

A: The general delivery time is 25-30 days after receiving your order confirmation.

Q: Do you provide sample ? Is it free?

A: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

Q: What is your term of payment?

A: 30% down payment before producing and 70% balance payment before shipping