This machine can achieve edge gluing, folding, paper rolling, bottom folding, bottom gluing, bottom molding, and one line bagging. It is easy to operate, efficient, and stable, effectively saving labor costs.

This machine can achieve edge gluing, folding, paper rolling, bottom folding, bottom gluing, bottom molding, and one line bagging. It is easy to operate, efficient, and stable, effectively saving labor costs.

|

Model |

GT-330T/330F |

GT-450T/450F |

GT-450BT/450BF |

GT-550T/550F |

|

Paper bag cutting length |

260-530mm 260-430mm |

260-530mm 260-430mm |

360-800mm 360-700mm |

360-800mm 360-700mm |

|

Paper bag width |

130/220-330mm |

150/250-450mm |

220/250-450mm |

220/250-550mm |

|

Paper bag bottom width |

70-180mm |

70-180mm |

100-250mm |

100-250mm |

|

Paper thickness |

60/80-160g/m2 |

60/80-160g/m2 |

60/90-160g/m2 |

60/90-160g/m2 |

|

Paper bag speed |

120-200pcs/min |

120-200 pcs/min |

120-200 pcs/min |

120-200 pcs/min |

|

Paper roll width |

430-1050mm |

570-1290mm |

670-1430mm |

670-1630mm |

|

Paper roll diameter |

Dia1200mm |

Dia1200mm |

Dia1200mm |

Dia1200mm |

|

Inner diameter of the paper roll |

Dia 76mm |

Dia 76mm |

Dia 76mm |

Dia 76mm |

|

Power |

25KW |

25KW |

30KW |

30KW |

|

Weight |

18000 KGS |

19500 KGS |

19500KGS |

23000KGS |

|

Dimension |

L12*W5.4*H2.6m |

L12*W5.6*H2.6m |

L13.5*W5.7*H2.6m |

L13.5 |

1. The human-machine touch screen interface, the work condition can be shown in real- time.

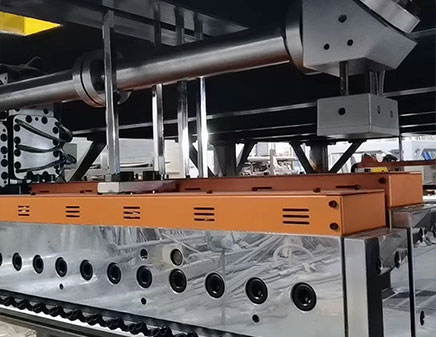

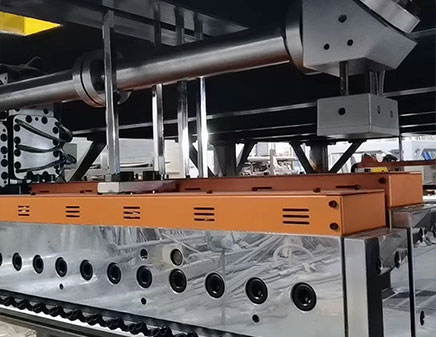

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3. Material loading and unloading adopts pneumatic or hydraulic lifting structure.

4. Automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving,long life.

6.Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Don't stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple, more time

saving.

8. Glue roller air defense coating control,avoid gluing on besmear brushs hub surface directly, reduce unnecessary trouble.

9. Accurate color tracking system, automatic alarm prompt when color is wrong.

10. Adjustable forming mould structure (side sealing is above the forming mould).

11. Handle production unit, paper handle cutting and gluing are all controlled by servo motor.

GET A QUOTE